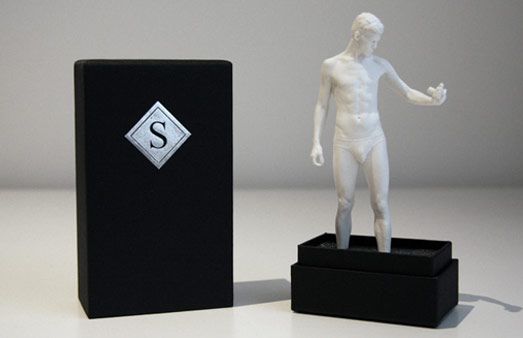

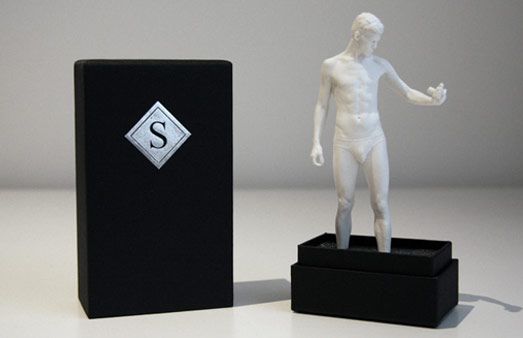

PD Models was happy to work with young British artist Stuart Sandford, to produce 10 limited edition six-inch vacuum casted statuettes, made to reproduce marble.

This was a great project to work on as it involved so many processes. To start with, a live model was 3D scanned by a London based company Sample and Hold using the latest high resolution 3D printing vowin.cn' target='_blank'>rapid prototyping and 3D scanning technology. Once we had the data from this, we used our 3D printer to create a master model that was hand finished and primed ready for the casting process.

Using this master model a silicone rubber “tool” or mould was made. From this the 10 statuettes were vacuum cast using resin that had been impregnated with marble dust and a few other ingredients in order to give the effect of white marble. The statuettes were then given a bit of hand finishing before they were ready to go on display.