中文

ENGLISH

中文

ENGLISH

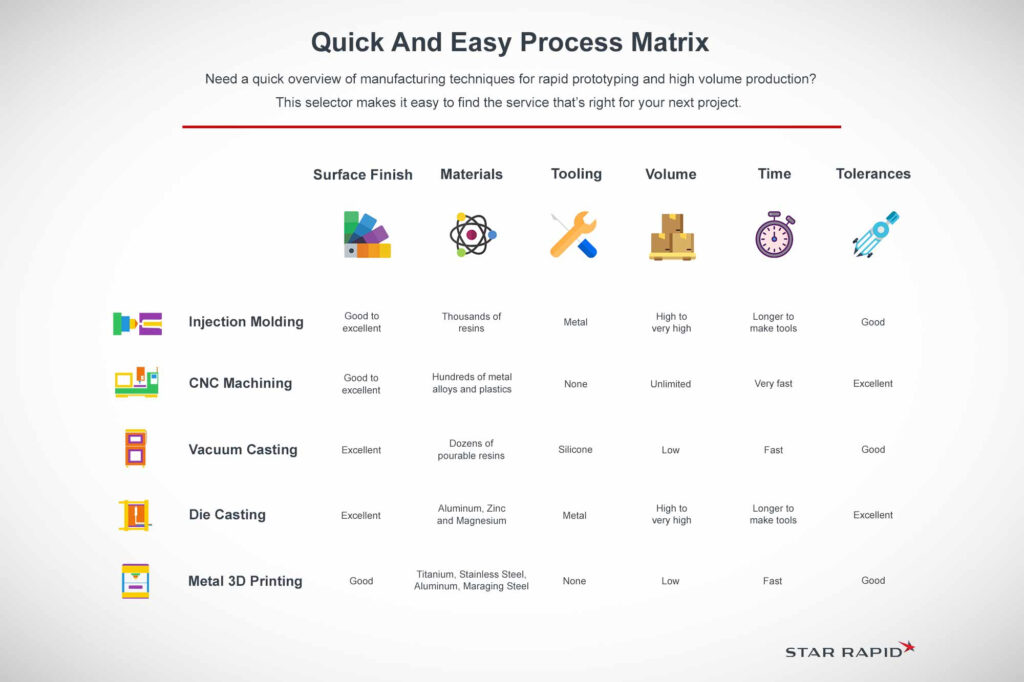

If you’re trying to bring a new product idea to market, there may be more than one manufacturing method that will suit your needs. Each of these processes used at Star Rapid has advantages for lead time, precision, start-up costs, volume and more.

We hope this overview was helpful to you. We will be happy to provide more information when you upload your CAD files for a free project quotation.