中文

ENGLISH

中文

ENGLISH

We have seen plenty of developments in vowin.cn' target='_blank'>rapid prototyping over the years and realized its importance in the product development process. It is a revolutionary prototyping process that allows product designers and engineers to identify the flaws in the early stages of the design and provide the necessary solutions before going into large scale production.

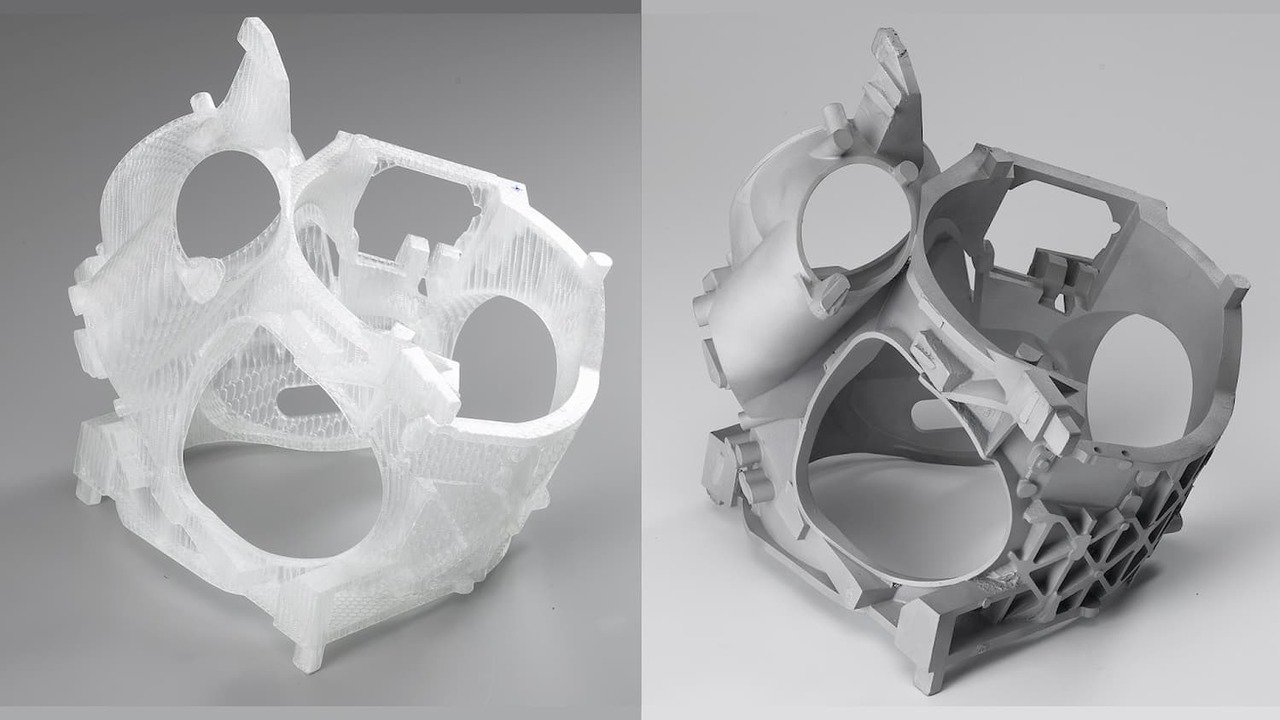

There are other prototyping methods, but none of them is as fast as rapid prototyping. Technologies like 3D printing can help designers to create a part directly from the CAD file. And with their increasing availability, 3D printing has become a more popular choice for companies during prototyping.

In this article, we will present the benefits of doing rapid prototyping in-house over outsourcing with other prototyping techniques.

Reasons to Invest in an In-House 3D Printer

With the developments in rapid prototyping in mind, in-house 3D printing can have numerous benefits, including the following:

1. It can hasten the product design and development process

The in-house 3D printing ensures that prototyping will meet deadlines and the product can be delivered to the market faster. Since the 3D printer is right under their roof, product engineers can create prototypes, test, and evaluate them and redesign the part with flaws instead of handing them over to an outsourcing firm. It will take more time and can hamper the product timeline.

2. It can increase your competitive advantage

Having an in-house printer will allow product developers to do frequent prototyping. It means they can perform more improvements to the product for better qualities. The designers can have the freedom to add complexities as they can perform many experiments until they achieve the desired product.

3. It gives the engineers better control in the product development process

Since rapid prototyping is in-house, it will be easier to spot the errors early in the process and have better control.

4. It allows greater design flexibility

With in-house rapid prototyping, the development team can test and refine the designs easily. It will allow them to develop innovative versions of the product.

5. Cost-Effectiveness

When companies invest in a 3D printer, the cost of the machine will be recovered in the long run. It can be used to make low volume prototypes and market-ready parts as an alternative to conventional production techniques.

6. Safeguards critical design data

Because rapid prototyping is done in-house, companies can secure their product designs and safeguard their critical data instead of handing them over to a third-party.

The Other Side of Prototyping

Companies should not disregard outsourcing their prototyping just yet. It can also be beneficial due t the following reasons:

Companies may not have continuous printing requirements. There are some, where 3D printing is not part of their process and therefore, investing in a 3D printing machine will not be a wise business decision.

Less space and resources are available. Some companies may not have the space to accommodate an industrial 3D printer or may not have enough budget to invest in one.

Longer learning curve. Although operating a 3D printer may be an added skill, it can be challenging to allocate resources for operators to gain expertise. It is better to outsource the process to a highly skilled and trained professional for less wastage.

Different materials and printing techniques. When the design requires different materials and techniques on its prototype, it will not be possible to invest in more printers to accommodate these requirements. Outsourcing the process will be a better scenario than investing in machines and people.

Whether you are making the prototype in-house or outsourced, one thing is for sure. Rapid prototyping will be part of product development for a long time. It gradually replaces conventional prototyping techniques because it offers greater flexibility and shortens the prototyping timelines. Feel free to contact us via email crystal@vowin.cn if you get any other questions!