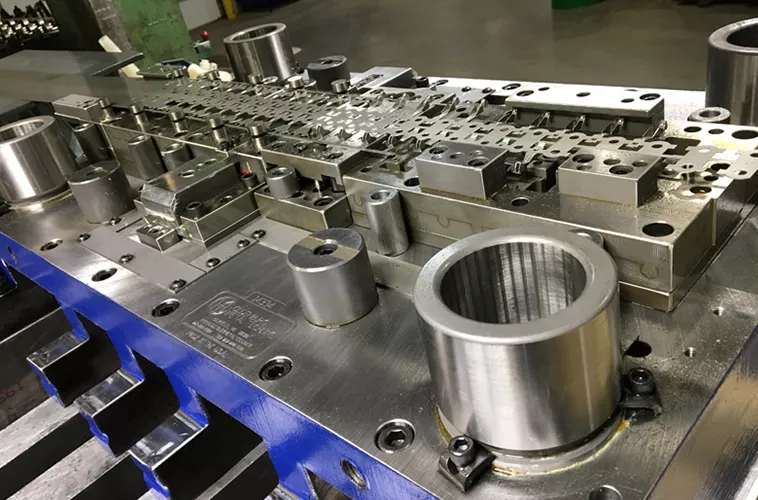

| Minimum Bend: | 1 Times Sheet Metal Thickness |

| Minimum Hole to Edge Distance: | 2 Times Sheet Metal Thickness |

| Minimum Hole to Hole Distance: | 6 Times Sheet Metal Thickness |

| Minimum Bend Edge to Hole Distance: | 6 Times Sheet Metal Thickness |

| Minimum Feature to Countersink Distance: | 8 Times Sheet Metal Thickness |

| Minimum Countersink Depth: | 1 Times Sheet Metal Thickness |

| Relief Cuts: | 1 Times Sheet Metal Thickness |

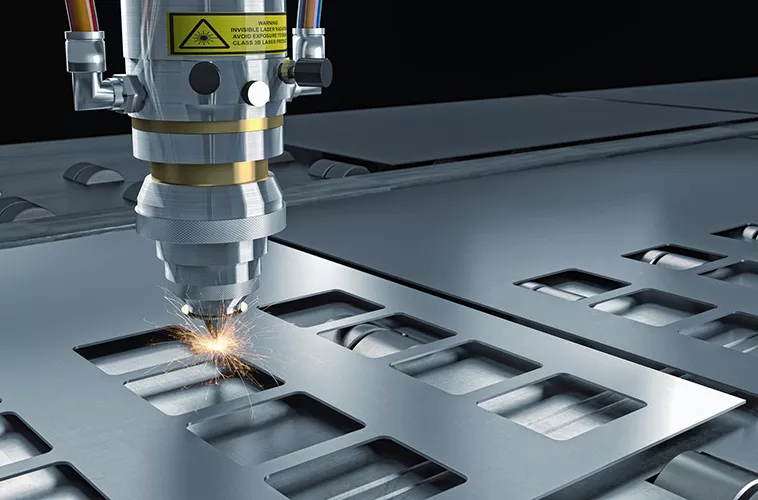

| Cutting Feature: | ± .00787’’ (0.2 mm) |

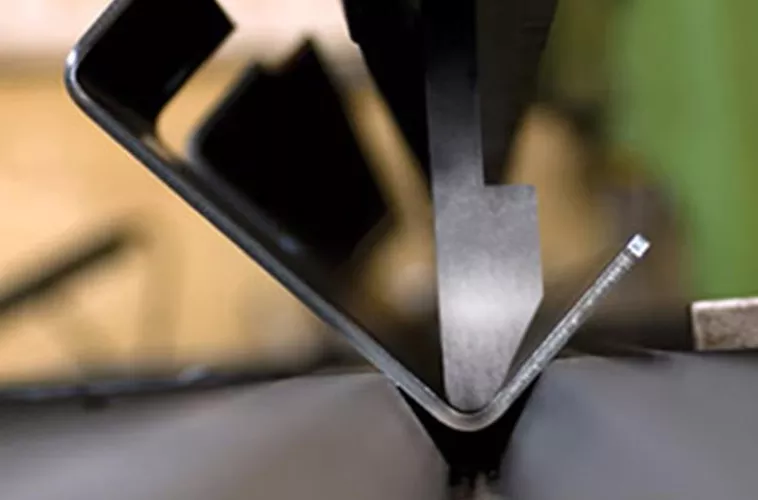

| Bend Angle: | ± 1.0° |

| Bend to Edge: | +/- 0.010” (0.254mm) |

中文

ENGLISH