中文

ENGLISH

中文

ENGLISH

What is CNC milling for metal?

What is CNC milling? CNC milling is a computer-controlled subtractive machining process that uses rotating cutting tools to remove material from a solid, stationary workpiece to create custom-designed parts. During milling, the workpiece is cut along

CNC milling is a computer-controlled subtractive machining process that uses rotating cutting tools to remove material from a solid, stationary workpiece to create custom-designed parts. During milling, the workpiece is cut along multiple axes to obtain a variety of shapes and geometries.

Our CNC milling services are simple: Upload your CAD files to our online instant quote system to get a quote, work with us to optimize your design and select your materials, then get your project into production quickly and efficiently.

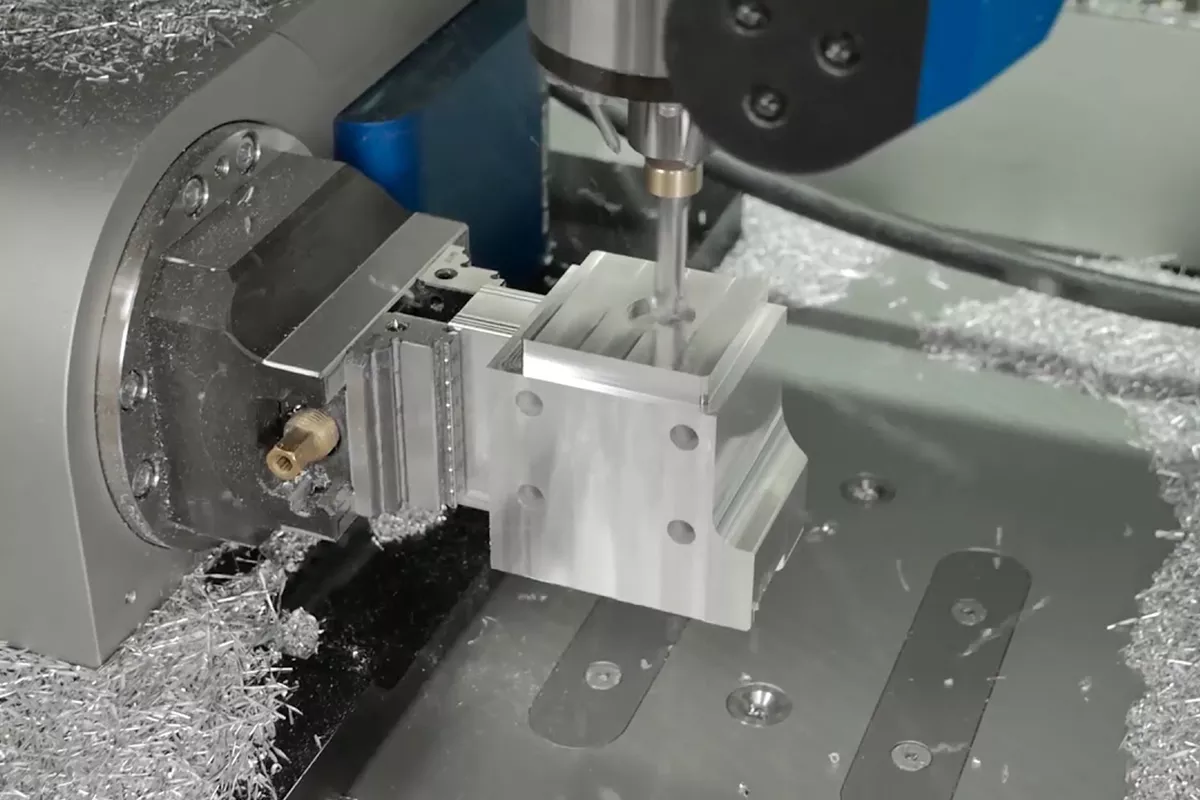

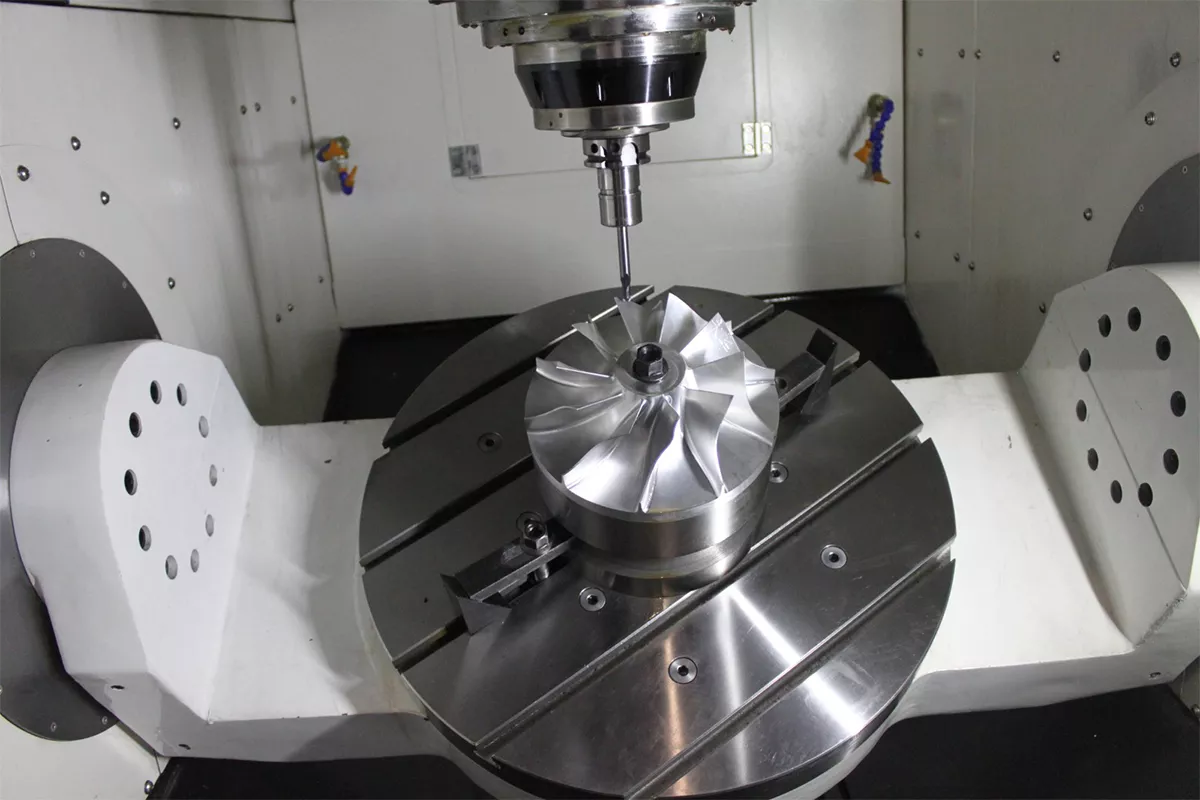

Our CNC machining capabilities include both 3-axis, and 5-axis mills:

A profitable and efficient solution to your CNC milling needs! We ensure the machining of parts with complex geometrical shapes, including undercut features, threaded holes, sharp edges, and planar profiles. Complete multiple operations through effective integration with an automatic tool changer. We can also design 3-axis milling centers to meet the unique requirements of each client.

Get more complex CNC milled parts with our 4-axis CNC milling. We consistently produce precise and accurate results, with greater control and more flexibility, even with complex shapes. Ensure cost-effective machining of angled features that are rather impossible with 3-axis machines. With more power, greater control, and higher precision, 4-axis milling is your ideal solution.

Machine complex custom CNC milled parts with a single setup. Our 5-axis CNC milling machines save time, improve efficiency, and reduce cost, ensuring that you meet market demands faster and cost-effectively. We can reach higher cutting speeds without excessive pressure on the cutter. Get rapid prototypes and low-volume production parts with better surface finishes.

At Rapid-MFG, we are committed to helping you reach your manufacturing goals. We constantly strive for effective solutions through our progressive technological approaches and machining techniques. Our CNC milling services ensure you get highly precise prototypes and production parts with superior quality.

The Rapid-MFG CNC milling process takes your project from prototype to production quickly and simply. Optimize your milled parts with the following design considerations, material choices, and finishing and post processing options:

CNC milling general process information

| 3-Axis Milling | 5-Axis Milling | |

|---|---|---|

| Maximum part size | 1800 x 1000 x 500 mm 70.9 x 39.4 x 19.7 in | 1000 x 900 x 600 mm 39.4 x 35.4 x 23.6 in |

| Minimum part size | 12.7 x 12.7 x 12.7 mm 0.5 x 0.5 x 0.5 in | 12.7 x 12.7 x 12.7 mm 0.5 x 0.5 x 0.5 in |

| Minimum feature size | Ø 1 mm Ø 0.039 in | Ø 1 mm Ø 0.039 in |

| Standard tolerance | Metals: +/-0.13 mm (0.005 in) Plastics: +/-0.20 mm (0.008 in) | |

| Minimum wall thickness | Recommended size: 0.8 mm (0.031 in) for metals and 1.5 mm (0.059 in) for plastics Feasible size: 0.5 mm (0.019 in) for metals and 1.0 mm (0.039 in) for plastics | |

| Holes | Recommended size: Diameter: standard drill bit sizes Depth: 4 x diameter Feasible size: Diameter: Ø 0.5 mm (0.019 in) Depth: 8 x diameter | |

| Threads | Recommended size: Size: M6 or larger Length: 3 x diameter Feasible size: Size: M2.5 | |

| Lead time | As low as 8 days for less than 50 parts | As low as 10 days for less than 50 |

We stock more than 30 production-grade plastic and metal materials that are suitable for various part applications and industries.

| Plastic | Aluminum | Stainless Steel | Other Steel | Other Metal |

|---|---|---|---|---|

| ABS | 2024 | 303 | Mild steel | Brass |

| Nylon 6 | 6061 | 304 | Alloy steel | Copper |

| Acetal (Delrin) | 6082 | 316 | Tool steel | Titanium |

| Polycarbonate | 7050 | 17-4 |

Contact us for additional metal machining options |

|

| PVC | 7075 | 420 | ||

| HDPE | ||||

| PTFE (Teflon) | ||||

| PEEK | ||||

| Nylon 30%GF | ||||

| UHMW |

Gain access to quality surface finishing for custom CNC milling parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | Learn More>> | |

|

Bead Blasting |

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. |

ABS, Aluminum, Brass, Stainless Steel, Steel |

n/a | Matte | Learn More>> | |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel |

Black, any RAL code or Pantone number |

Gloss or semi-gloss |

Learn More>> |

|

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. |

Aluminum, steel, stainless steel |

n/a |

Smooth, glossy finish |

Learn More>> |

|

| Polishing |

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. |

Aluminum, Brass, Stainless Steel, Steel |

n/a |

Glossy |

Learn More>> |

|

|

Brushing |

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. |

ABS, Aluminum, Brass, Stainless Steel, Steel |

n/a | Satin |

Learn More>> |

Competitive

One to One Service

Enginner Review

Quality

Fast Delivery

Request Quote Right Now

By clicking "Accept", you agree to the storing of cookies on your device to enhance site navigation,

analyze site usage, and improve marketing. we never collect any personal data.