中文

ENGLISH

中文

ENGLISH

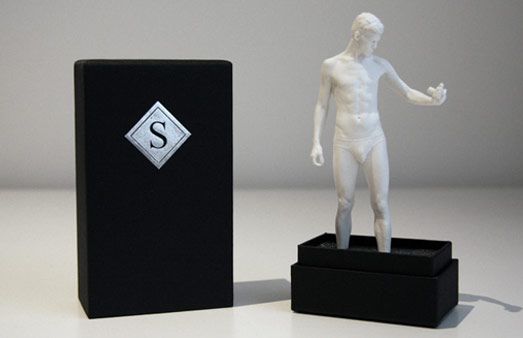

Using this master model a silicone rubber “tool” or mould was made. From this the 10 statuettes were vacuum cast using resin that had been impregnated with marble dust and a few other ingredients in order to give the effect of white marble. The statuettes were then given a bit of hand finishing before they were ready to go on display.