Plastic Injection Molded Parts Vs Aluminum Casting Parts

Plastic injection

vowin.cn/en/News/news1251.html' target='_blank'>

vowin.cn/' target='_blank'>molding and aluminum die casting are the most 2 popular methods for producing components. They are suitable for mass production but also for low volume manufacturing. They are similar and different.

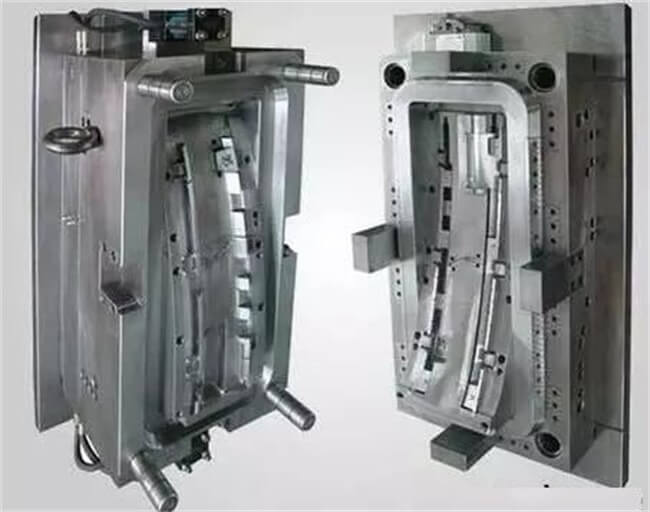

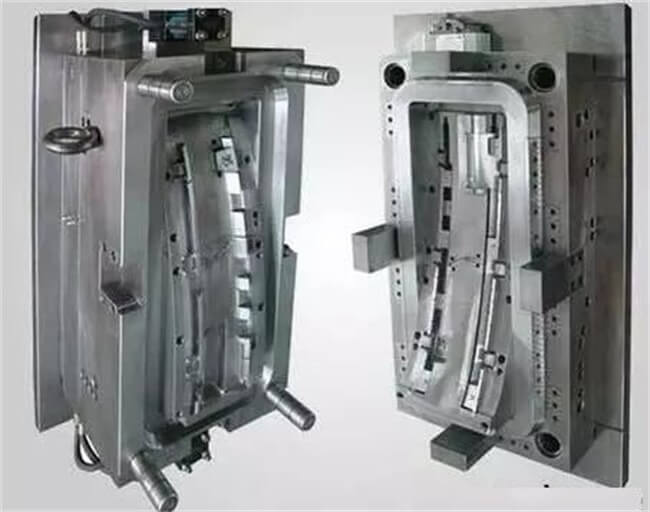

Plastic Injection Mold Parts

Advantages:

1. The melting temperature of plastic part is lower than aluminum parts.

2. In same design, product in plastic is lighter than in aluminum.

Disadvantages:

1. Plastic

injection molded parts usually require metal inserts to hold a thread for screws.

2. Plastic does not block EMI/RF waves.

3. Compare to aluminum part, plastic part is not strong.

4. Plastic is not typically biodegradable.

Aluminum Parts

Advantages:

1. Part can be threaded directly on hole.

2. Can apply post

machining to obtain high precision dimension.

3. Aluminum

casting part has great thermal transference properties.

4. Aluminum is a natural conductor of electricity.

5. All aluminum alloys (360, 380, 383, and 413) are made from recycled materials.

6. Comparing to plastic parts, aluminum parts are stronger/

7. Aluminum naturally shieds EMI/RF waves.

Disadvantages

1. In the same design, product in aluminum weighs heavier than plastic.

2. Aluminum parts usually needed post machining and post finishing.