Engineering and Design Supports for Rapid Tooling

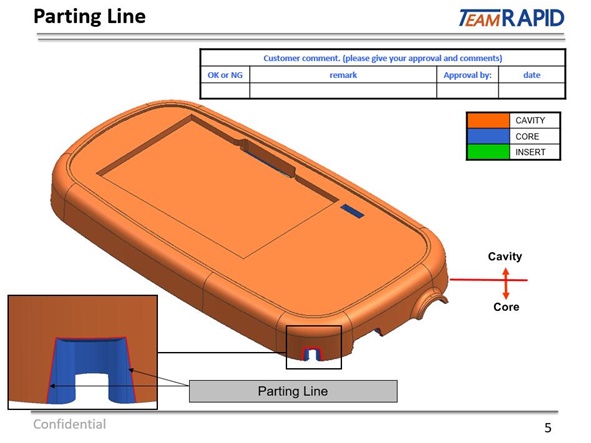

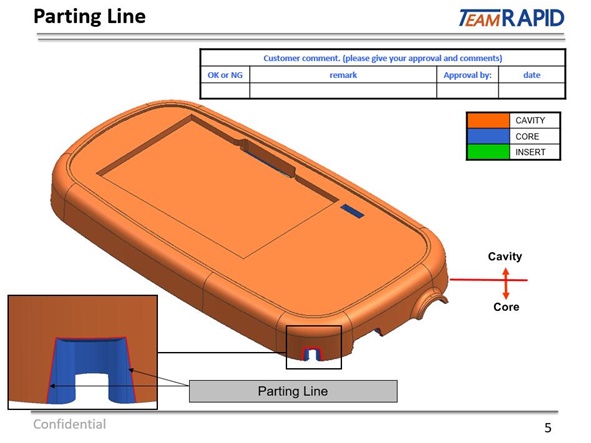

At Vowin Rapid, most of our engineers have over 10 year experience in the tooling field. We can provide professional DFM (Design for Manufacturability) to our customers in the name of design optimisation before tooling, this greatly cuts down any potential quality risks that limit launching into the market quickly.

Advantages of DFM

Advantages of DFM

- Optimizes the design and greatly cuts down any quality issues caused by design defects. This helps to reduce any costs associated with late changes or revisions once production has begun.

- Shortens the cycle of new product introduction and listing.

- It is conducive to manufacturing and can simplify the process.

While it varies based on a part’s complexity, the DFM can be prepared in only one or two days.

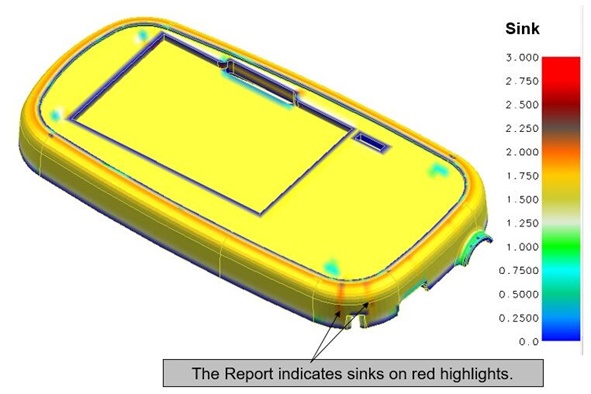

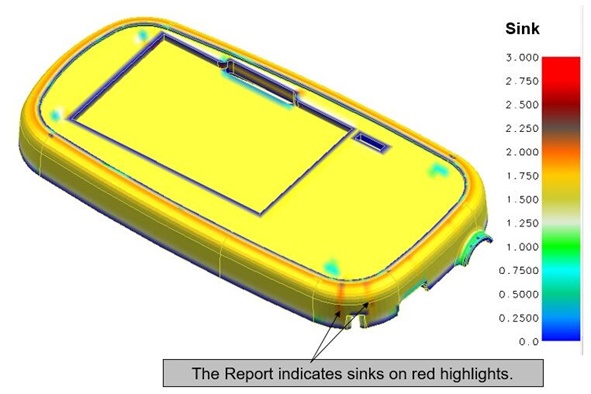

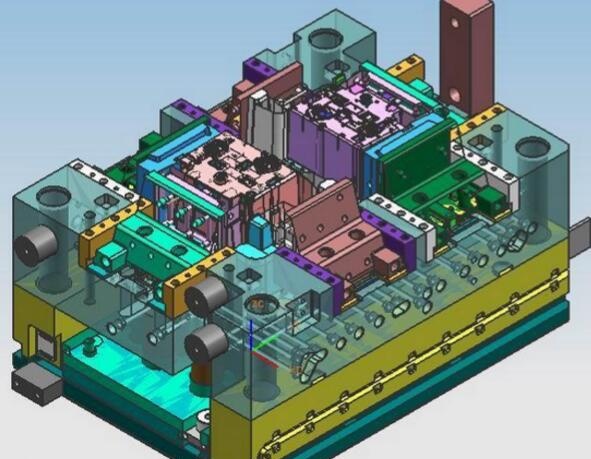

MFA(Mold Flow Analysis) Service

MFA(Mold Flow Analysis) Service

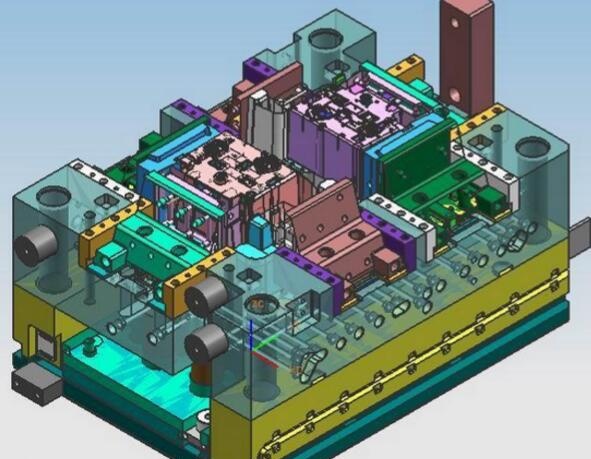

Meanwhile, we provide MFA(Mold Flow Analysis) service if the customer has special requirements. We use data simulation software to assess the feasibility of the

vowin.cn/' target='_blank'>

mold structure and improve the

vowin.cn/' target='_blank'>

mold and

product design. Through data simulation, it is easy to see the problems in the injection and

Rapid Tooling and revisit the design process prior to production if necessary. This virtual simulation can greatly save on “trial and error” costs by quickly solving early problems that may be encountered.