中文

ENGLISH

中文

ENGLISH

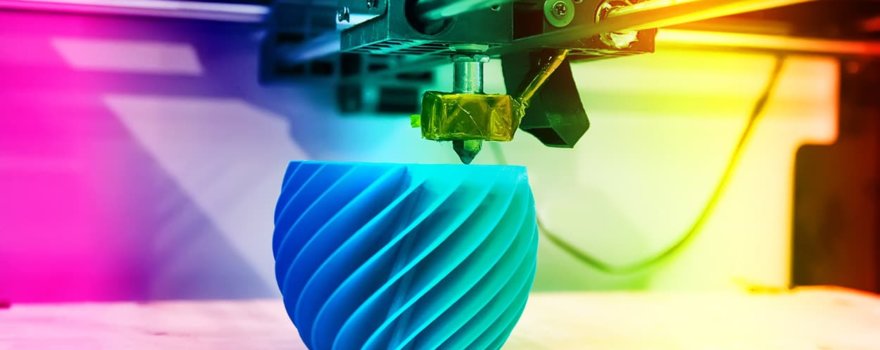

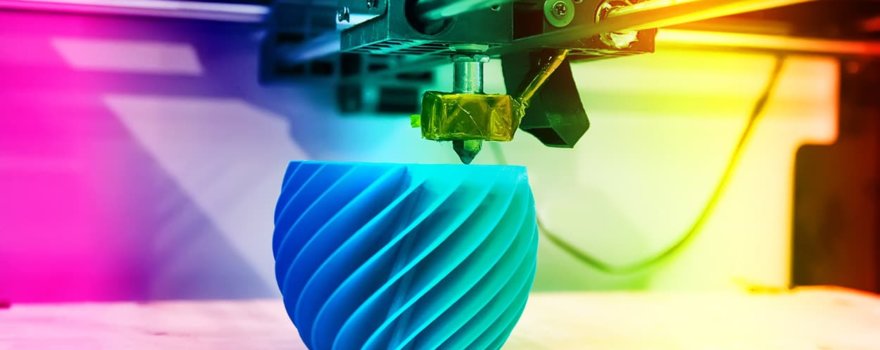

As we enter a more eco-conscious era of manufacturing, there are tons of concerns that new technologies are possibly taking us backwards. The concerns often levied at 3D printing put its abundant use of plastics and power usage under fire, and sometimes these arguments are valid. However, players within the industry are doing their best to come up with valid solutions that can assuage such grievances. Many designers are looking to new technolgies, materials and alterations within the supply chain to make 3D printing more sustainable and environmentally friendly. Here are just some of the big ways how:

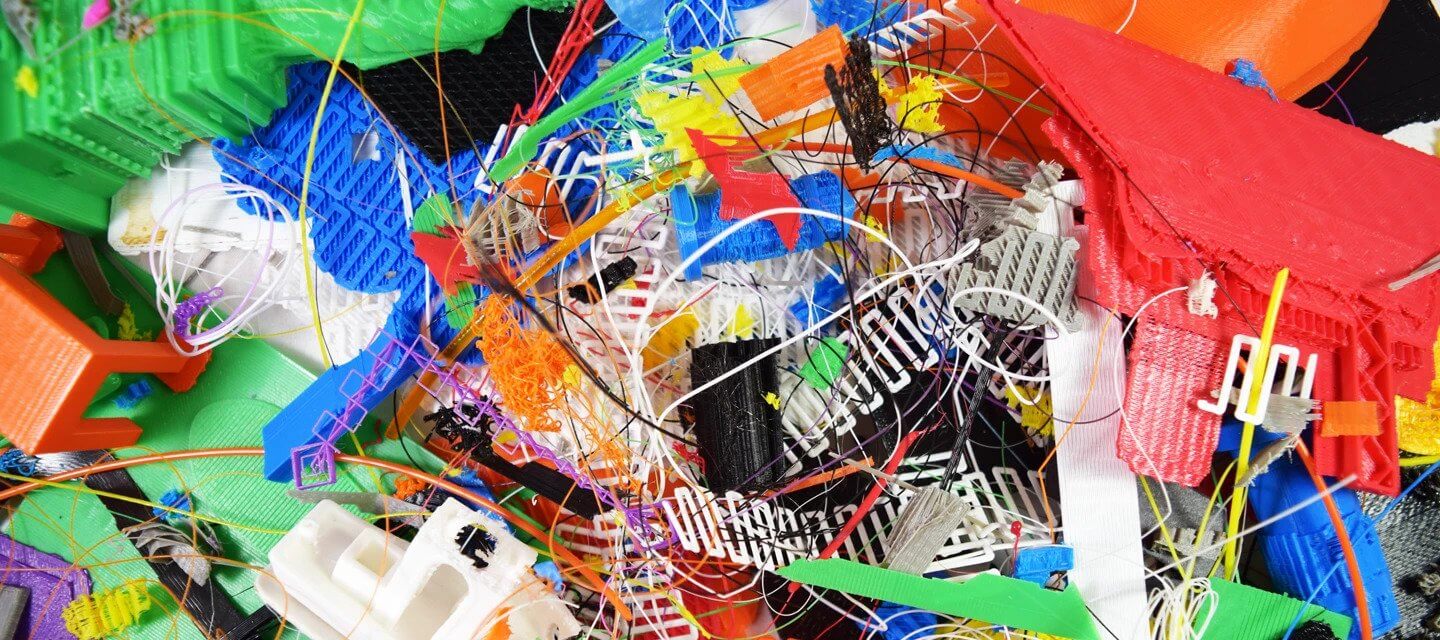

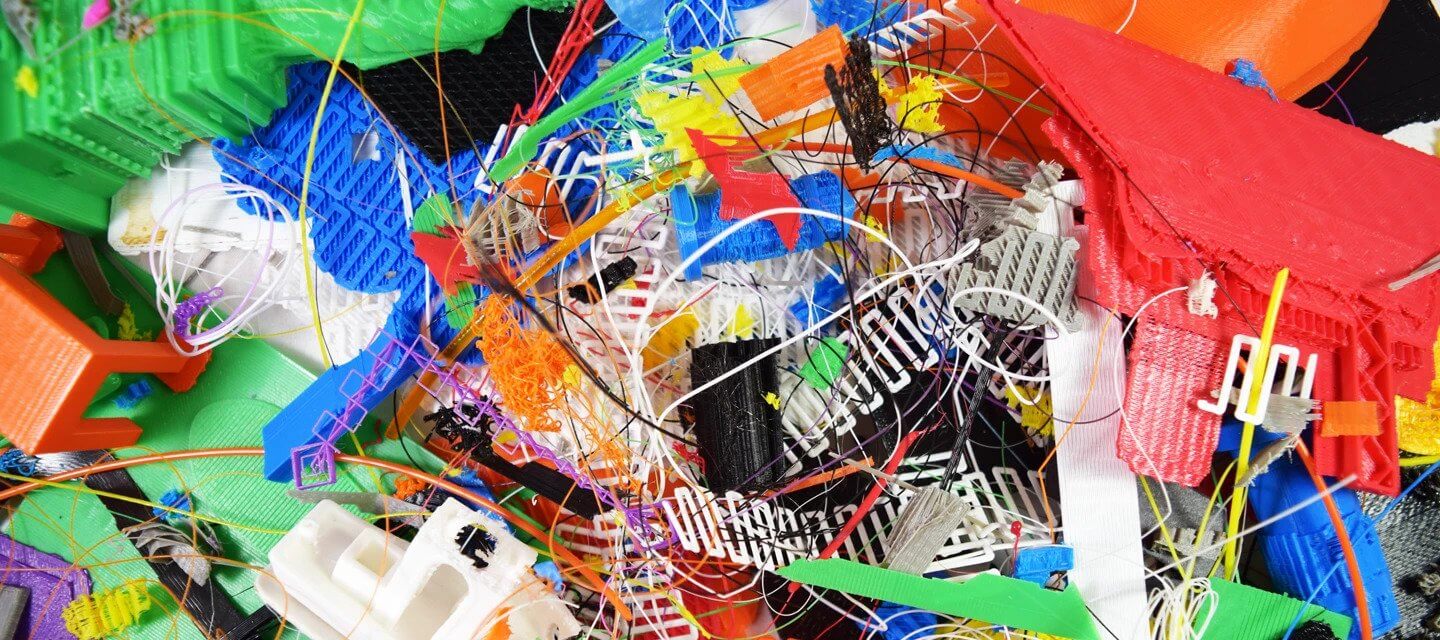

Recycling filaments is not just better for the environment, it’s also a good practice to have on hand within your own workshop or business. Whether its failed prints, botched jobs or just clutter in your work-space, recycling old prints or items can be good. Some companies are already filling this particular gap in the market with some nifty items like filament recycling kits, while others are upping the ante and cleaning industrial plastics on a much larger scale.

On the more ambitious side, companies like Clean Currents are optioning specialty 3D printers that can be totally compatible with ocean plastic, allowing users to help clean the environment as they print their items. Other companies like Trimatis LLC are taking plastic waste and turning it into filament as well. This has been such a promising possibility even the US military is looking to 3D print with recycled plastic from obsolete parts to both save on transport costs and be more efficient.

Similarly, companies like 3devo provide filament shredders and spool-making tech so that users can get in on reusing their old plastics rather than tossing them out. Other users that are making pellets out of old plastics have an even easier job on their hands.

However, there’s more than just recyclable filaments and pellets on the material front.

While PLA (one of the most commonly used materials in 3D printing) is biodegradable, not all other additive manufacturing thermoplastics are. However, why should we have filaments made of non-biodegradable plastics at all? There are multiple other options researchers have been coming up with that entirely eschew these environmentally unfriendly options while offering some novel material characteristics.

New technologies are allowing for a range of materials to be used for 3D printing for unique purposes. One such material comes in the form of MIT’s antibacterial 3D printed cellulose filament. It could potentially become a powerhouse for medical applications, making it easy to create FDA-approved materials that can be discarded without causing much concern about sustainable waste disposal. It is also quite resistant in terms of mechanical properties and inexpensive to produce.

Another potential technology that could be worth noting is that of bioplastic hemp filaments that companies are developing. 3D4MAKERS is one company that produces such a filament, offering pretty good adhesion between layers.

Even aside from filaments, there are a number of promising materials in the world of 3D printed constructions that could make for some very enticing options for potential architecture projects. Various projects have been looking for sustainable means of producing concrete, a product whose production leads to a large portion of greenhouse gas emissions (The cement sector is the third-largest industrial energy consumer and the second-largest industrial CO2 emitter globally). That’s why companies like FICEP S3 created systems that reuse the waste products from 3D printing and post-processing parts in processes like MJF and SLS, creating a new hybrid concrete. Project BCN is thus looking to take waste to turn it into a more sustainable form of mixed concrete that may offer fewer of the headaches associated with traditional manufacturing materials.

Similarly, organic compounds are also being used for 3D printing houses. These compounds aren’t just an eco-friendly curiosity either, as some of these offer solutions that can allow for the rapid printing of structures. Estonian University of Life Sciences and the University of Tartu have been experimenting with Peat, a natural material made from decomposing vegetation that forms in bogs and other wetland environments. As one of the most efficient carbon sinks on the planet, it can store carbon compounds which makes it particularly useful in this endeavor. It has been used as an important source of fuel in certain parts of the world for over a century and scientists have found a way to turn it into an organic source of housing that actually aids environmental efforts as opposed to hindering them. Such a process also makes use of waste, aiding in recycling.

Other researchers have been working with soil 3D printing, such as the project for transforming lunar regolith. These experiments are edging us closer towards using alternative materials that are more abundant while recycling old elements to create new constructs.

3D printers are going to consume a lot of energy as they become more common within wider industries. However, this doesn’t mean that the energy has to come from traditional means. Solar power is still very much developing but it represents the holy grail of alternative energy, and many companies are tapping into this by both developing solar panels with 3D printers and directly harnessing solar energy for additive manufacturing devices.

3D printed solar panels offer some distinct advantages. These can be lighter, cheaper and, in certain cases, printing them provides a lot less waste. Methods like MJF have been used for 3D printing solar systems for a while now. Nano Dimension has been particularly notable in this regard, teaming up with start-ups in Israel to produce such sustainable energy solutions. Some companies are even developing flexible ones, which is a prospect that would not be possible with traditional manufacturing.

3D printing is also helping boost the efficiency of solar panels. T3DP, for example, is a 3D printing research project that began in 2013 under the leadership of Daniel Clark. Its aim is to use a patented volumetric 3D printing to double the conversion efficiency of current solar panels. Essentially, T3DP is trying to create a 3D printed solar which is affordable and viable. Their work employs prior research studying the chemical compound perovskite materials for solar cells, which can provide far stronger and stable materials for building solar cells.

On the other hand, some companies have been developing 3D printers that run on solar energy. Such concepts have been available on as open-source technologies for a long time. Even aside from their environmental benefits, such printers are a useful prospect in that they allow for printing in remote areas. This was the impetus behind re:3D’s work with the Gigabot, which is an off-the-grid 3D printing device that could potentially bring additive manufacturing to areas without electricity by harnessing the power of the sun.

As we enter a more eco-conscious era of manufacturing, there are tons of concerns that new technologies are possibly taking us backwards. The concerns often levied at 3D printing put its abundant use of plastics and power usage under fire, and sometimes these arguments are valid. However, players within the industry are doing their best to come up with valid solutions that can assuage such grievances. Many designers are looking to new technolgies, materials and alterations within the supply chain to make 3D printing more sustainable and environmentally friendly. Here are just some of the big ways how:

Recycling filaments is not just better for the environment, it’s also a good practice to have on hand within your own workshop or business. Whether its failed prints, botched jobs or just clutter in your work-space, recycling old prints or items can be good. Some companies are already filling this particular gap in the market with some nifty items like filament recycling kits, while others are upping the ante and cleaning industrial plastics on a much larger scale.

On the more ambitious side, companies like Clean Currents are optioning specialty 3D printers that can be totally compatible with ocean plastic, allowing users to help clean the environment as they print their items. Other companies like Trimatis LLC are taking plastic waste and turning it into filament as well. This has been such a promising possibility even the US military is looking to 3D print with recycled plastic from obsolete parts to both save on transport costs and be more efficient.

Similarly, companies like 3devo provide filament shredders and spool-making tech so that users can get in on reusing their old plastics rather than tossing them out. Other users that are making pellets out of old plastics have an even easier job on their hands.

However, there’s more than just recyclable filaments and pellets on the material front.

While PLA (one of the most commonly used materials in 3D printing) is biodegradable, not all other additive manufacturing thermoplastics are. However, why should we have filaments made of non-biodegradable plastics at all? There are multiple other options researchers have been coming up with that entirely eschew these environmentally unfriendly options while offering some novel material characteristics.

New technologies are allowing for a range of materials to be used for 3D printing for unique purposes. One such material comes in the form of MIT’s antibacterial 3D printed cellulose filament. It could potentially become a powerhouse for medical applications, making it easy to create FDA-approved materials that can be discarded without causing much concern about sustainable waste disposal. It is also quite resistant in terms of mechanical properties and inexpensive to produce.

Another potential technology that could be worth noting is that of bioplastic hemp filaments that companies are developing. 3D4MAKERS is one company that produces such a filament, offering pretty good adhesion between layers.

Even aside from filaments, there are a number of promising materials in the world of 3D printed constructions that could make for some very enticing options for potential architecture projects. Various projects have been looking for sustainable means of producing concrete, a product whose production leads to a large portion of greenhouse gas emissions (The cement sector is the third-largest industrial energy consumer and the second-largest industrial CO2 emitter globally). That’s why companies like FICEP S3 created systems that reuse the waste products from 3D printing and post-processing parts in processes like MJF and SLS, creating a new hybrid concrete. Project BCN is thus looking to take waste to turn it into a more sustainable form of mixed concrete that may offer fewer of the headaches associated with traditional manufacturing materials.

Similarly, organic compounds are also being used for 3D printing houses. These compounds aren’t just an eco-friendly curiosity either, as some of these offer solutions that can allow for the rapid printing of structures. Estonian University of Life Sciences and the University of Tartu have been experimenting with Peat, a natural material made from decomposing vegetation that forms in bogs and other wetland environments. As one of the most efficient carbon sinks on the planet, it can store carbon compounds which makes it particularly useful in this endeavor. It has been used as an important source of fuel in certain parts of the world for over a century and scientists have found a way to turn it into an organic source of housing that actually aids environmental efforts as opposed to hindering them. Such a process also makes use of waste, aiding in recycling.

Other researchers have been working with soil 3D printing, such as the project for transforming lunar regolith. These experiments are edging us closer towards using alternative materials that are more abundant while recycling old elements to create new constructs.

3D printers are going to consume a lot of energy as they become more common within wider industries. However, this doesn’t mean that the energy has to come from traditional means. Solar power is still very much developing but it represents the holy grail of alternative energy, and many companies are tapping into this by both developing solar panels with 3D printers and directly harnessing solar energy for additive manufacturing devices.

3D printed solar panels offer some distinct advantages. These can be lighter, cheaper and, in certain cases, printing them provides a lot less waste. Methods like MJF have been used for 3D printing solar systems for a while now. Nano Dimension has been particularly notable in this regard, teaming up with start-ups in Israel to produce such sustainable energy solutions. Some companies are even developing flexible ones, which is a prospect that would not be possible with traditional manufacturing.

3D printing is also helping boost the efficiency of solar panels. T3DP, for example, is a 3D printing research project that began in 2013 under the leadership of Daniel Clark. Its aim is to use a patented volumetric 3D printing to double the conversion efficiency of current solar panels. Essentially, T3DP is trying to create a 3D printed solar which is affordable and viable. Their work employs prior research studying the chemical compound perovskite materials for solar cells, which can provide far stronger and stable materials for building solar cells.

On the other hand, some companies have been developing 3D printers that run on solar energy. Such concepts have been available on as open-source technologies for a long time. Even aside from their environmental benefits, such printers are a useful prospect in that they allow for printing in remote areas. This was the impetus behind re:3D’s work with the Gigabot, which is an off-the-grid 3D printing device that could potentially bring additive manufacturing to areas without electricity by harnessing the power of the sun.

Any questions:crystal@vowin.cn